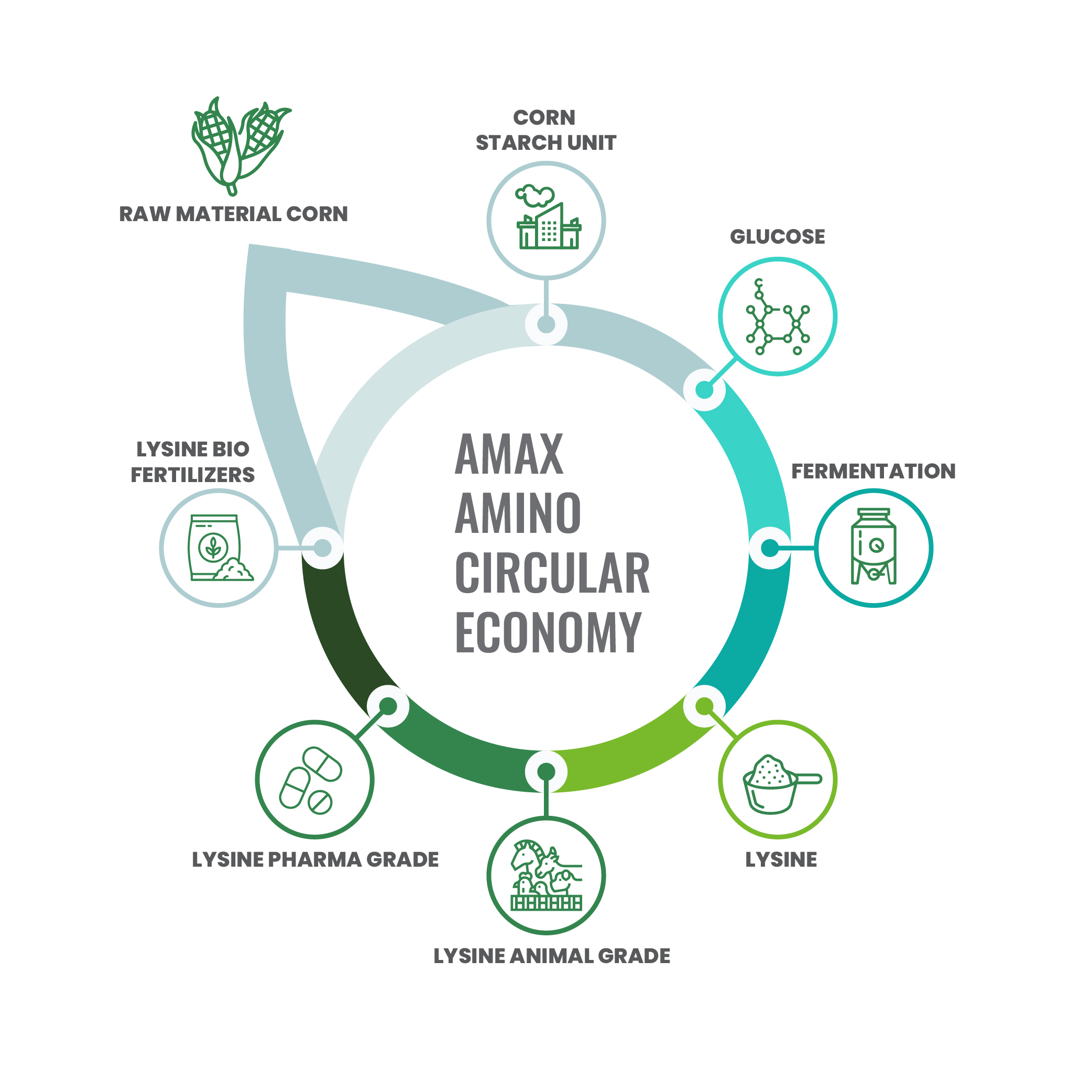

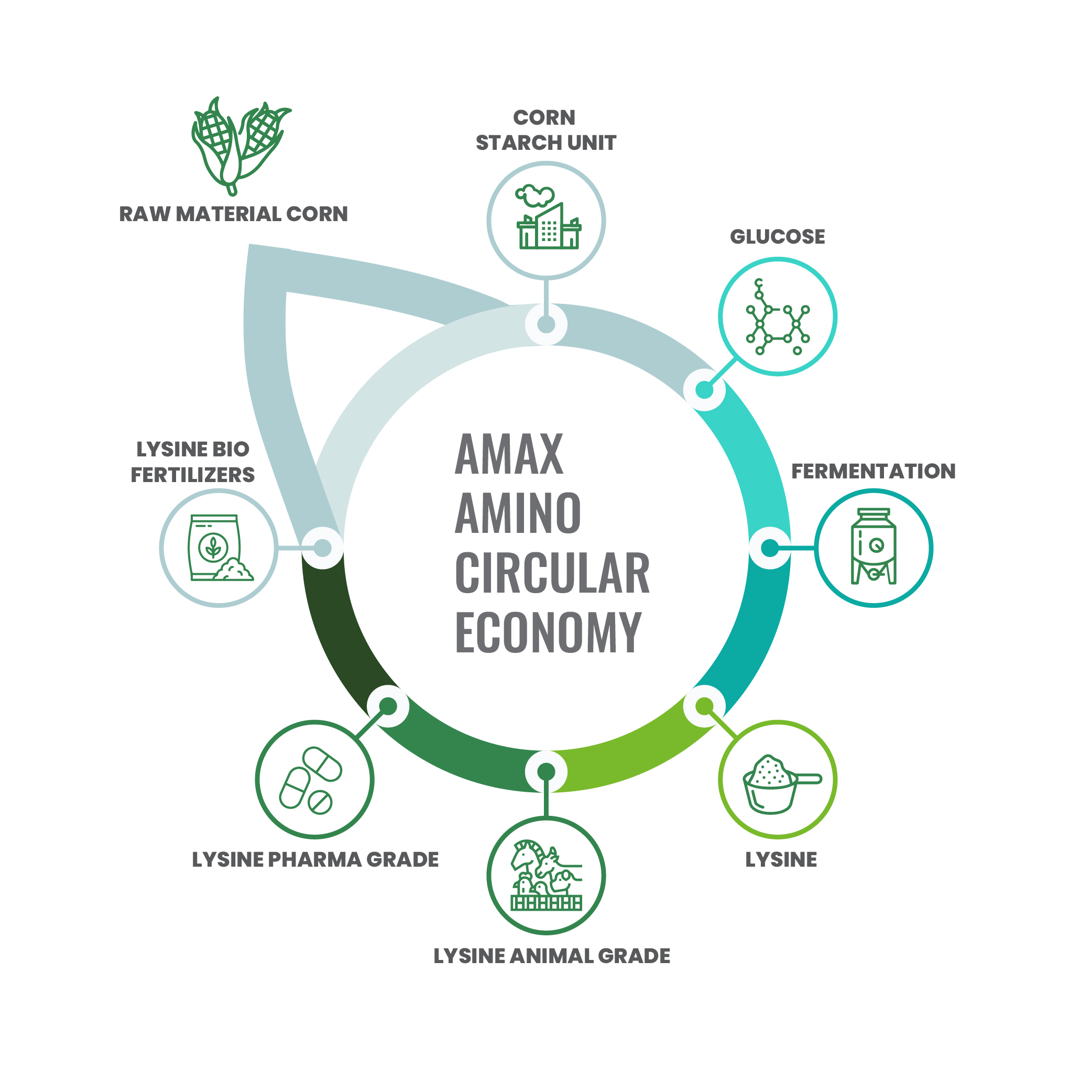

In pursuit of sustainable sourcing for lysine production, key considerations encompass the establishment of supply chain traceability, ensuring the responsible sourcing of raw materials through collaboration with ethically committed suppliers that uphold fair labour practices and environmental stewardship. Additionally, fostering a circular economy or closed looped economy by exploring opportunities to recycle or reuse by-products generated during lysine production plays a crucial role in waste reduction. Moreover, active engagement with local communities is vital to promote sustainable agricultural practices, providing support to farmers and fostering economic development in the regions where lysine raw materials are sourced.

Reducing waste in lysine production is achieved through a comprehensive approach encompassing efficient raw material utilization, lean production practices, stringent quality control, inventory management, energy and water efficiency, waste separation and recycling, employee training, data monitoring, and continuous improvement. By optimizing raw material extraction, minimizing overproduction, and implementing energy-efficient technologies, producers can decrease waste generation and minimize costs. Effective waste separation and recycling further divert materials from landfills, while ongoing employee training and data analysis ensure a culture of waste reduction and continuous improvement, fostering a more sustainable and resource-efficient lysine production process.

Reusing waste generated during lysine production is a sustainable practice that involves identifying valuable components within by-products and repurposing them within the production process or other industries. This can be achieved through processes like recycling fermentation residues into biofuels or feedstock, or directly reusing certain waste materials as fermentation substrates or in other production stages. Collaborative efforts with sectors like agriculture can explore the reuse of by-products as soil conditioners or organic fertilizers, creating economic and environmental benefits. Stringent compliance with environmental and safety regulations ensures the responsible handling of reused materials, contributing to a circular economy and reducing waste disposal while conserving resources and minimizing the environmental footprint of lysine production.

While certain organisations may be proceeding at a slower pace, Amax Amino is actively embracing circularity. We recognize the growing awareness and concern among our customers regarding environmental impact and their quest for innovative sustainability and circular solutions that contribute positively to the environment.

Amax Amino remains dedicated to our vision, standing as a committed steward for our planet.